Brake Line Installation

Brakes lines are similar to electrical systems in that many folks do a very poor job of repairs or replacement. Taking your time on the installation and aquiring proper tools really pays off as it is not only important for safety but can produce a really clean result. Matt's car was a great example of this with very poorly installed stainless steel lines which were not routed well and had improper flares which actually damaged mating surfaces on the MC and other parts. SS is much harder to work then standard lines, without the proper tools the job is that much harder.

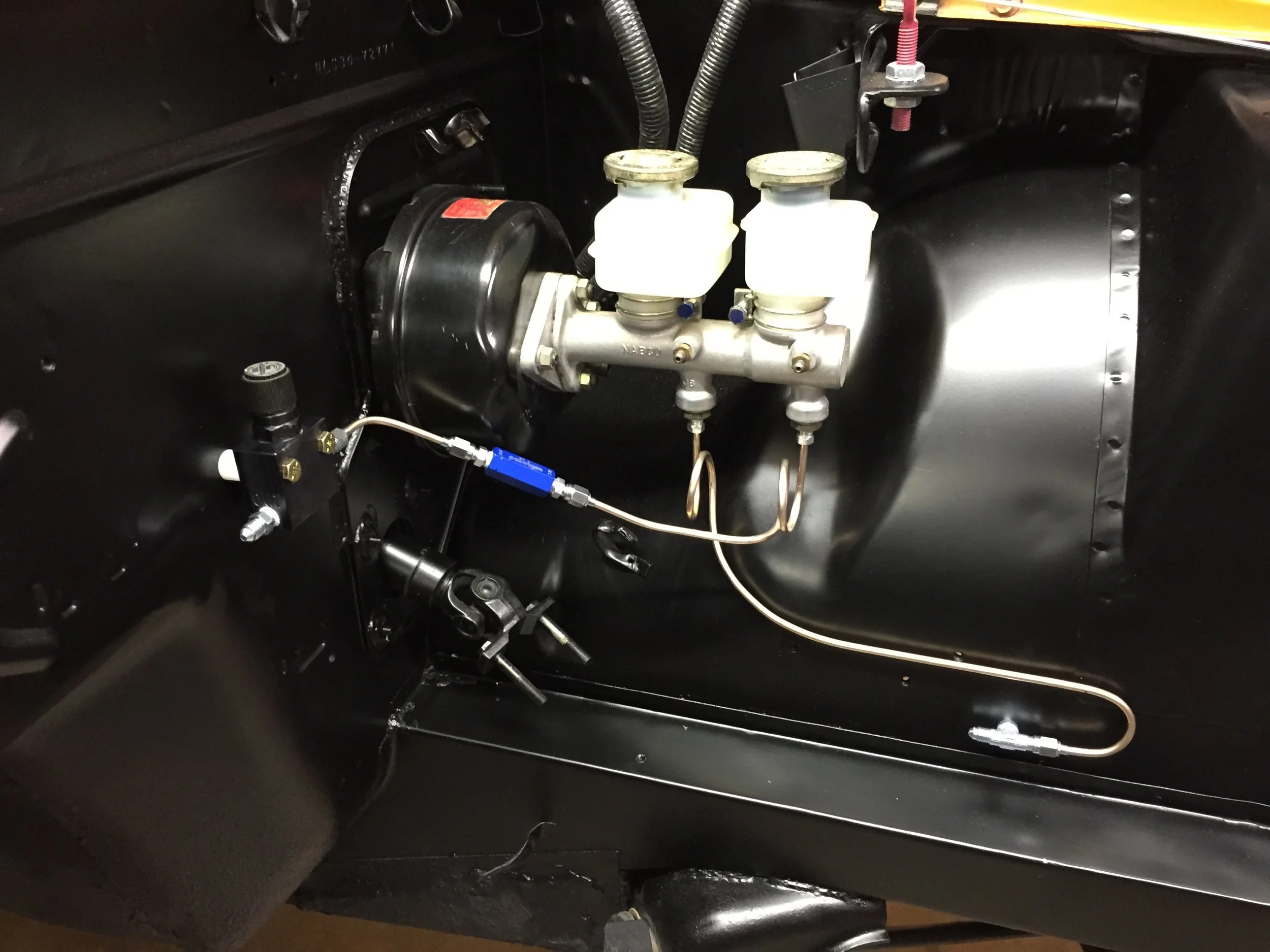

With everything stripped out of the engine bay for cleanup it was a geat time to tackle all new brake lines. NiCopp lines with AN (37Deg) fittings were used throughout the car. Nicopp line will not corrode over time and is very easy to form. AN fittings gave us alot of options for routing, like 90's, bulkheads, and a splitters. The only place OE 45deg fittings were installed was the master cylinder.

A couple hundred dollars spent on brakes tools is a good investment for any avid hobbist. I highely reccomend the vise mounted flare tools offered by Eastwoord. The base kit along with a set of AN dies allows you to tackle most plumbing jobs up through -6AN. A cheap tubing cutter, tube bender, and tube pliers rounds out everything you will need to get the job done.

I started maing templates for each section using aluminum welding wire and then replicated them with NiCopp. This method works well and with Nicop it is easy to make adjustments by hand as you go. The install was finished up with braided stainless lines to the calipers.

Sorry for the light pictures, I need to document the rear lines and claiper connections next time the car is in the shop!